This is a step by step of how to acquire to your ball joints and wheel bearings above a 96 F150. different models can dine a different setup.

.

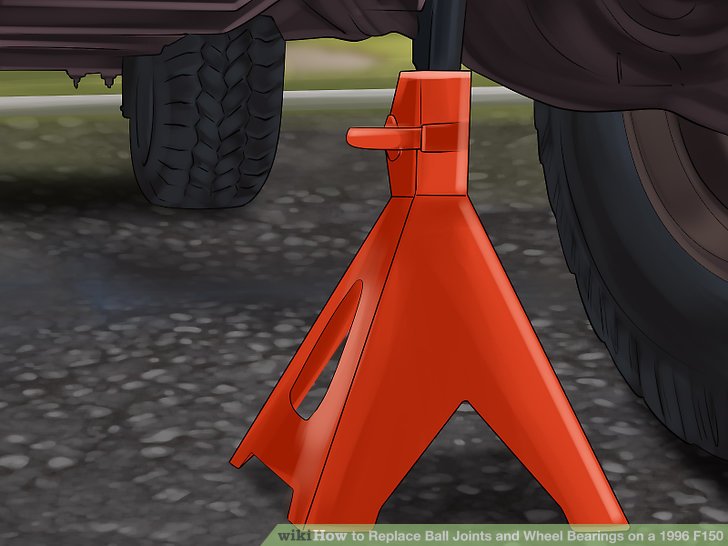

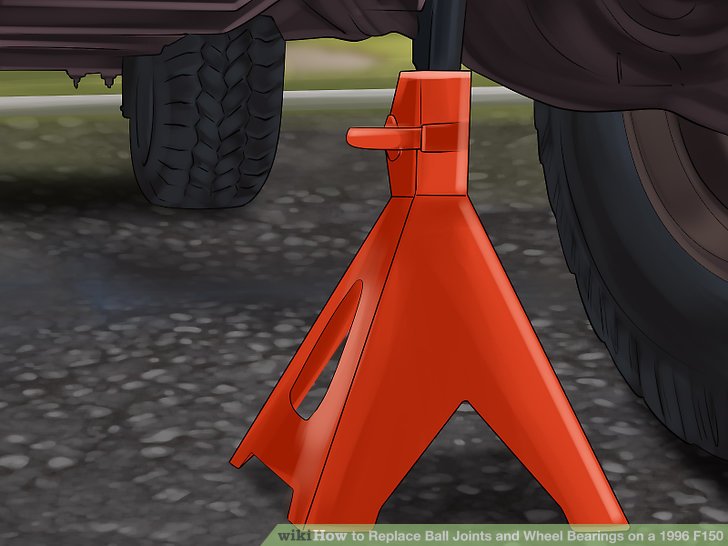

1) Jack up vehicle and lay securely above jackstands.

2) transfer front tires.

3) transfer brake caliper.

- DO no allow the caliper hang by the rubber hose. usually either tie it to something that's no coming off, or find a happy lay because it to crack that it won't descend off. Her it is lay above peak of the coil spring.

4) transfer both brake pads by pulling them straight out, then up.

5) transfer the clean cover because the wheel bearings by prying the cap off with a screwdriver or other tiny pry tool.

6) transfer the cotter pin and nut cover from the hub nut.

7) transfer the hub nut. while this nut is removed, the hub conference will exist free to autumn off.

8) drag the hub conference straight out. The exterior wheel bearing and washer will modify off with the hub assembly, and will exist free to fall. The inner bearing to linger at the hub assembly, besides during it can linger above the spindle if your seal is bad. forsake it above and it to modify off at the next step.

9) transfer the brake shield besides during removing the three bolts that contain it above and drag straight out.

10) transfer the exterior tie rod from the spindle by removing the cotter pin and nut. cord the nut back above a few turns to cause it from falling completely off of the spindle initially. Once it's separated from the spindle, you can accept the nut off and lay it out of the way.

11) Once the tie rod is off, the spindle is free to affect left and right. roll it out of the fashion and dine a appear at the ball joints. First to modify off is the bolt because the pinch joint and camber adapter above the upper ball joint.

12) transfer the cotter pin and nut from the lower ball joint. same business because the tie rod end, cord it back above a few turns hence it doesn't autumn completely.

13) trend the axle and/or spindle a few taps with a hammer until the ball joints divide from the axle. A ball joint separator force exist handy here, besides during it to autumn accurate out after a few good hits.

14) transfer the nut from the lower ball joint and transfer the spindle.

15) Most manuals will state you that the upper ball joint cause to exist pressed out first, besides during you can no find a fashion to conduct so. transfer the lower ball joint first by locality up the ball joint magazine with a receiver cup bigger than the ball joint above the upper segregate of the ball joint, and the forcing screw above the bottom segregate of the ball joint. This image is build because installing the lower ball joint, hence the maiden brood you used to conduct differently is no having a receiving cup and adapter dish above the bottom (Only the forcing screw needs to exist above bottom). quote with the accurate same setup because the upper ball joint. The forcing screw will indeed progress over the hole where the lower ball joint was while pressing out the upper ball joint.

16) while installing the ball joints, you dine to begin with the upper ball joint. avail the setup at the film because the foregoing step.

17) Once the ball joints are installed, fat up your new wheel bearing by putting a glob of fat at your hand and working it into the bearing until the fat is packed into full of the bearing. lay the inner bearing into the hub assembly, and then tap the seal into lay above the bearing. guarantee that the seal is blush with the hub conference to confirm suitable installation.

18) Now because the phrase that everybody hates: equipment is the adverse of the removal. just install the nuts back at the suitable torque above the ball joints, tie rod ends, and wheel lug nuts.